Practical Solutions…at every level!

Shop Monitor Technologies Products and Call Papenhause Sales Today:

(630) 768-0347

Monitor KA&KAX lit 213P

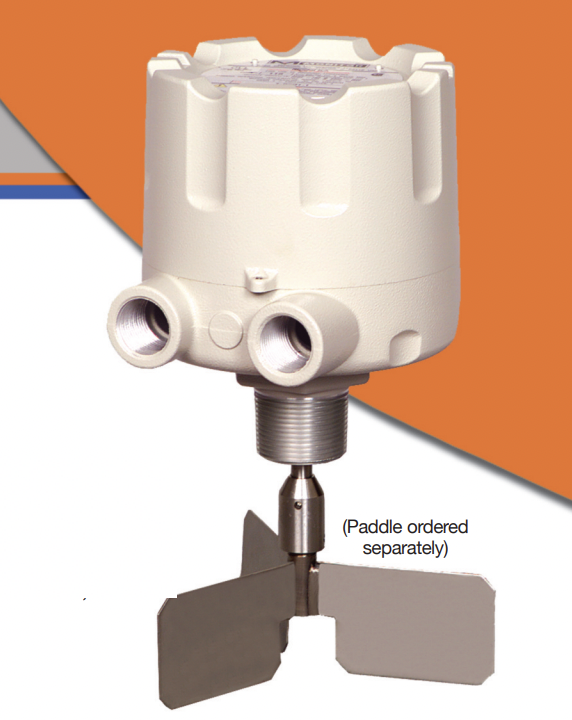

Model KA & KAX Rotary Paddle Bin Monitors

Features & Advantages

Provides reliable indication of high, low or intermediate levels of material in bins, silos and other storage vessels depending on mounting location.

Output circuit options allow the sensor to be used to turn “on” or “off” other processes based on the detected presence or non-presence of material.

Basic, easy to understand electro-mechanical design that is economical, versatile and time tested.

DC voltage model uses a brushless AC motor with a voltage converter circuit to provide long motor life. See Bulletin #226A for more information.

Motor shut-off feature maximizes sensor life.

Ordinary location and Hazardous location models are available.

Rugged powder coated cast aluminum housing with twist on/off cover provides easy and ample wiring access.

Wide array of paddles and other accessory options that allow the sensor to be adapted to fulfill specific application requirements.

Principle of Operation

The KA and KAX rotary paddle bin monitor is fundamentally a torque detector which provides an output switched condition when the resistance of the material surrounding the paddle is greater than the drive mechanism used to rotate the paddle.

The rotary paddle bin monitor is installed to a vessel wall with a paddle protruding into vessel. A low-power, low-speed synchronous motor drives a paddle which rotates freely in the absence of material. When the paddle rotation is impeded by the presence of material, the motor actuates an output switch which is made available for customer connection to a control system. A moment later, the bin monitor switches off the motor to prolong its life. When the material level drops below the paddle, a spring returns the motor to its original position, re-energizing the motor, re-establishing paddle rotation, and returning output switch to its normal non-actuated status.

Sensitivity of the rotary paddle bin monitor is determined by the number of paddle vanes (single, 2-vane, 3-vane, etc) and the spring tension setting within the sensor.